About Rheon(Spirits and Technology)

Message from Rheon for the Future

The origins of bread baking can be traced back to approximately 10,000 years ago. It was an age in which culture based on the creation of "taste" was sown through fruits and vegetables provided by nature. Since then, for many centuries, different food cultures throughout the world have been established. These traditions and customs of various countries have been passed on for many generations up to the present day.

Rheon has been keeping a watchful and respectful eye on this immense and irreplaceable aspect of culture, and has been considering ways to connect it with a better lifestyle for mankind.

The development of the automated food production technology by Rheon was the result of this observation. As a true pioneer in its field, the work of Rheon has had immeasurable effects on the food production industry throughout the world.

Food culture, created through the wisdom of mankind, is one of the greatest treasures that the earth holds.

Preserving and fostering its growth is among the important tasks of today's scientists and engineers. Rheon, for its part, remains committed to upholding the "Rheon Spirit" as a creator continually striving for finer tastes.

-Encrusting Machine-

The company name, "RHEON" was derived from the concept of Rheology. In the several thousand year history of mankind, man has shaped food in the palm of his hand, hence creating and shaping much of the priceless culture which exists today.The shaping of these foods not only created an art form, but also originated many delicious tastes.

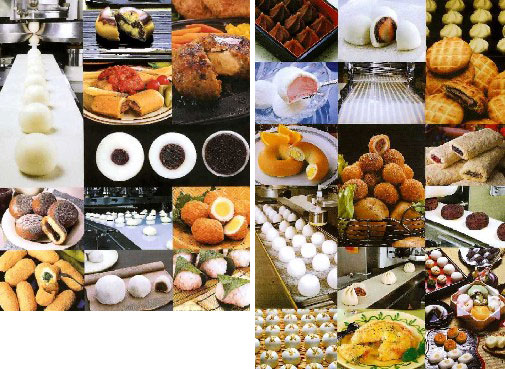

Rheology is the study of the flow and deformation of matter;and Rheological Engineering is the shaping of food, by means of skillfully manipulating its "viscosity" and "elasticity", to maintain the delicate texture of the food as the taste and aroma are locked inside. Rheon has succeeded in automating the production of various ethnic foods worldwide through the original theory of Rheology and Rheological Engineering. Today, Rheon stands as an internationally recognized company in the food processing machinery industry.The photo on the left shows the action of the rotating discs resembling that of a human palm. The skillful, accurate, and high-speed production of "Manju(Japanese cakes with sweet bean-paste filling)" truly demonstrates Rheon's principle of Rheological Engineering.

The outer circumference of each disc generates the calculated tangential stress and normal stress, draws the dough into the cutting section, and automatically encrusts the filling.The dough is then molded into a round shape.Rheon's new technology which reproduces the traditional technique, that required six processes, completes the job, in a single process. When Rheon was established in 1963, the company introduced to the world the inductive shaping method, which brought attention to Rheological Engineering as a new field of study.

Rheon's Stress Free®Method

Rheon's applied rheological engineering technology continuously forms a thin dough sheet with negative stress on the dough. No more rolling, no more unnecessary pressure!

Rheon has uniquely developed the system, "From Dough Sheet to Various Breads". A wide variety of breads from around the world can now be produced with just a single line!

Bread was the first processed food made by mankind. In the course of time, various types of "cuisine" were originated, and tastes which never existed before were created.

These creations have brought to us the value of the present food culture.

The number of different cuisines around the globe has become immeasurable, and continues to cultivate peace, love and contentment in our style of eating and manner of living.

We must be appreciative and respectful to the wisdom of our ancestors who first discovered this very complicated process of bread making. Starting by cracking small and hard grains, flour is then milled, and water is added to finally create the dough. The dough is rested overnight and formed into a small dough ball. This dough ball is further left for fermentation to produce dough with fine air bubbles. The dough is then ready for baking to create flavorful and nutritious high-quality bread with a long shelf life.

Numerous attempts have been made to facilitate the difficult process involved in bread making. Today, only Rheon offers "Stress Free®" bread production technology.

Rheon's applied rheological engineering offers the new "Stress Free® System" to create damage-free dough during the forming process.

Rheon strongly supports preserving priceless cultures of various countries by improving labor conditions and enhancing the valuable meaning behind each culture. Rheon would like to emphasize that the purpose in automating bread production is not only to facilitate the entire production procedure.

If the steps taken to automate the production have any flaws, the original taste and shape of each product will be sacrificed. This will cause the culture to lose its genuine aspects, and the traditional food culture will eventually disappear.

To ensure that these problems are prevented, Rheon has developed the system, "From Dough Sheet to Bread". Bread dough is conventionally formed by dividing a large dough block into small portions, and forming round, bar, or flat shapes.

However, this process applies stress to the dough during the dividing process, greatly damaging the gel and cell structures. The dough will not be able to produce air bubbles, resulting in poor-quality bread. Therefore, it has been essential to use some chemical additives for strengthening the dough structure, and to undertake extra processing to recover the damaged dough structure after dividing.

Rheon has made it possible to eliminate this time-consuming process by forming continuous thin dough sheets prior to the dividing process. While forming the dough into thin layers, the dough binding is strengthened to create any form of bread product. This is the "Stress Free® System".

Principle of Cultural Economics

Many friends from various parts of the world have visited Rheon headquarters located in Utsunomiya city. Welcomed by warm sound of a crackling fire, valuable time has been shared together through exchanges of thoughts and ideas.

Rheon's philosophy on management is clearly stated in the "Principle of Cultural Economics", which is based on the concept that creation of consumption is a cultural activity in itself, and its study is an important part of the activities of the company.

Since the dawn of history, ideas to make life more enjoyable have led to artistic expression in the form of dancing, music and painting. Cooking has also developed into an art along these lines, not only as a means for staving off hunger, but as a part of our desire for a cultured lifestyle.

As culture became more deeply a part of society, economic activities became necessary for the first time, when society becomes economically active its culture is further strengthened.

As long as a good balance in the relationship between culture and economy is maintained, international business will be warmly received.

Since its founding, Rheon has been performing on the stage we call the world, establishing strong, overseas ties. This has been based upon that wisdom common to all mankind known as science, and directed at the pride common to all mankind known as civilized eating.

In 1963, Rheon started a revolution in food processing technology. As a truly global enteprise, Rheon's personal philosophy has led to an international business approach that bypasses all global trade friction.

(Handmade quality products realized with Rheon Encrusting Machines.)

An imaginative combination of various flavors is created by a single machine. Well-matched tastes are encrusted to create an endless variety of products!