Equipment introduction

MM Line System

■A compact and fully automated production line for layered dough products.

With the New System, high quality puff pastries and Danish pastries are produced automatically at high efficiency.

- Features

-

The New System MM Line features...

1) Easier cleaning and maintenance

2) Improved safety measures and durability

3) User friendly low profile design

MM Line realizes the most efficient Pastry production by its fully automated process of "roll-in", "layering", "sheeting" and "shaping".

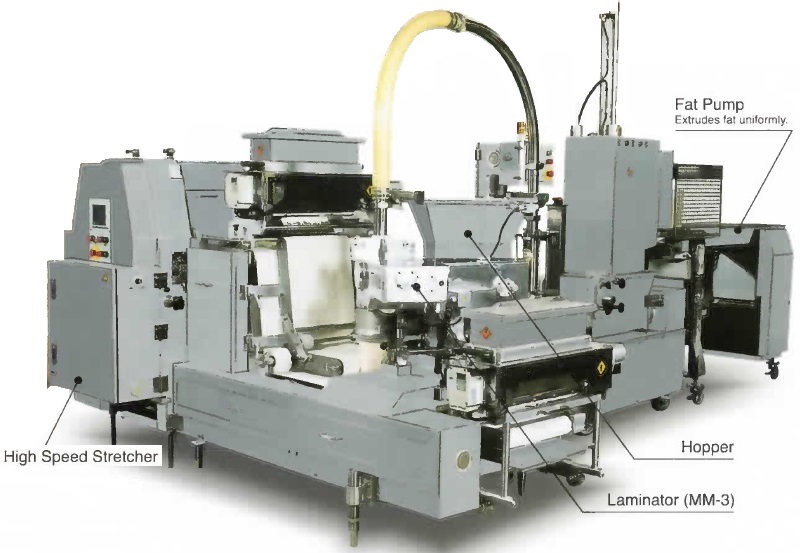

New-type Laminator (MM-3)

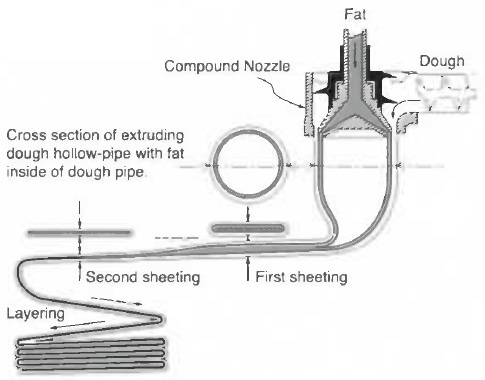

Continuous and uniform "roll-in" process by tubular co-extrusion of dough and fat.

Placed at the beginning of the system, Laminator (MM-3) continuously layers dough and fat with the highest precision.

Placed at the beginning of the system, Laminator (MM-3) continuously layers dough and fat with the highest precision.

Here the Compound Nozzle continuously co-extruders tubes of fat and dough from separate hoppers, and forms a uniform layer of fat inside a hollow dough tube without two materials blending together.

The tube is then stretched out gently by the stretcher into a uniform width and thickness dough sheet and folded into layers for the next step.

The tube is then stretched out gently by the stretcher into a uniform width and thickness dough sheet and folded into layers for the next step.

The range of roll-in amount is increased and adjusted easily with a new inverter control system. Stress Free® High Speed Stretcher

A High Speed Revolving System of independently rotated stretching rollers stretch out the dough sheet into a very thin dough sheet without exerting any stress to the dough.

Stress Free® High Speed Stretcher can stretch the dough sheet without distorting the Parallel Piler.

Within an operating distance of less then one tenth of its original thickness.

Stress Free® System assures damage-free dough sheeting to realize the production of high quality pastries with uniform structure.

Also with the much easier cleaning and maintenance features, the hygienic and safe production is achieved. The stretcher's stretching capacity is affected by dough type and consistency.

Stretching section automatically opens and closes by just a click of a switch makes a cleaning job very easy.

Principal Equipment of the MM Line

MM Line consists of the following 7 main components:

1) Laminator(MM-3)

Laminator(MM-3) is a roll-in system positioned at the beginning of the MM Line.

2) Fat Pump(Optional)

Connected to the Laminator(MM-3) and supplies roll-in shortening, margarine, etc. into the Laminator nozzle uniformly. Fat feeding method is selectable from two systems. "Center Cylinder Hopper" or "Fat Pump".

3) Pile-up Conveyor

Dough sheet with a fat layer from Laminator(MM-3) is folded onto this conveyor to determine the number of layers before being transferred to the Stress Free® Stretcher.

4) Stress Free® High Speed Stretcher

Stretches the dough sheet efficiently with a combination of rollers and the stretching roller.

5) Parallel Piler

When additional layers are needed, the Parallel Piler is positioned after the Stress Free® Stretcher, to refold the multi-layer dough sheet into further layers for re-stretching.

6) Make-up Table and Options

Stretched to the final dough thickness, the dough sheet is automatically formed into individual products by shaping attachments on the Make-up Table. These attachments include the Circular Cutter, Depositor, Side Winder, Folding Unit and Guillotine Cutter. All options, excluding the Guillotine Cutter, can be freely rearranged in the table.

7) Control

The highest standards in safety are maintained through emergency stop buttons located on the control panels and all along the line. In an emergency, each of these buttons bring the entire line to an immediate halt.

PMU-Control System

A computer-controlled central operating device can be installed if requested when ordering. This central operating device can store production data for up to 200 different products. By simply inputting the pre-recorded product number, the control panel automatically adjusts the settings on each machine to satisfy the conditions necessary for production, such as dough width, and speed synchronization of machines.

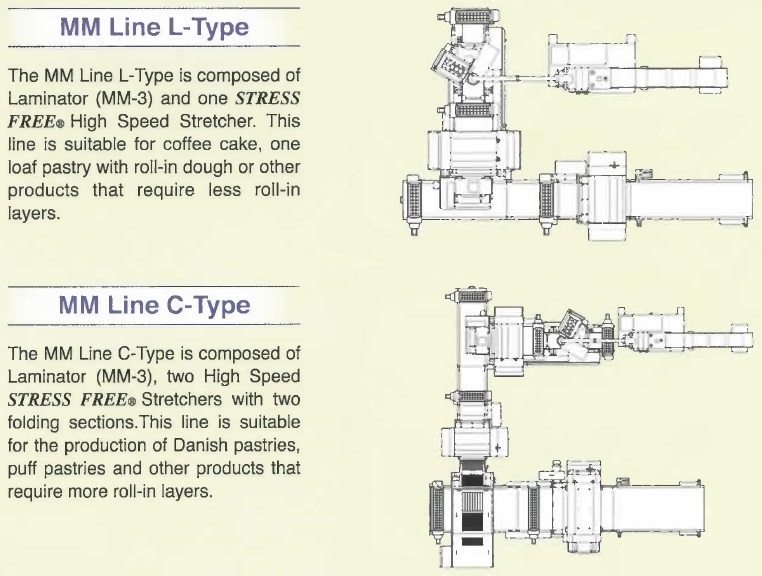

MM Line Configuration

Different capacity MM Lines are available to suit the demands of differing product varieties and through put.

To satisfy differing product output needs, Rheon supplies lines with maximum dough widths of 400mm, 600mm, 800mm, and 1200mm.

The MM Line can be custom-designed for special product requirements and factory space limitations.

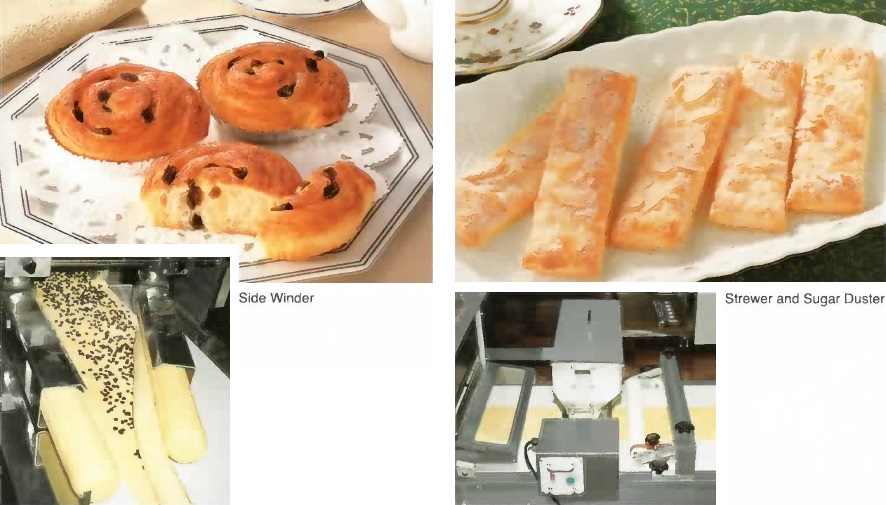

The vast line of shaping attachments expand the forming variations and product varieties; puff pastries, Danish pastries, Croissants and much more.

Twister, Twist & Carling Unit, Croissant Rotary Cutter, Croissant Molder

Twister, Twist & Carling Unit, Croissant Rotary Cutter, Croissant Molder Side Winder, Strewer and Sugar Duster

Side Winder, Strewer and Sugar Duster Depositor, Curcular Cutter and Blade Wheel, Guilotine Cutter, SlitCutter

Depositor, Curcular Cutter and Blade Wheel, Guilotine Cutter, SlitCutter Folding Unit, Guilotine Cutter, Half Moon Cutter

Folding Unit, Guilotine Cutter, Half Moon Cutter

- Specifications

(The specifications are subject to change without notice and without obligation.)Output Capacity 700 - 1500kg/h at 40% roll-in Piler Max. Swing Speed 27 strokes / min. Piler Swing Width 200 - 400 mm